A circuit is required to switch the power modules to construct the AC waveform to drive the motor.

The circuit uses PWM usually between 2 and 12 KHz. This fast switching stresses capacitors and other components. A significant quantity of power module failures are due to problems in this circuit.

The circuit uses PWM usually between 2 and 12 KHz. This fast switching stresses capacitors and other components. A significant quantity of power module failures are due to problems in this circuit.

The power supply generates all the voltages required to run all the other processes in the drive.

The power supply is vulnerable to age related component deterioration due to a trade off between size and heat dissipation.

The power supply is vulnerable to age related component deterioration due to a trade off between size and heat dissipation.

Most drives have fans to keep the heatsink cool. These can be on permanently or may be controlled when the drive is under load, depending on the manufacturer.

Failure of the fans causes an increase in temperature which usually results in an "over temperature" fault. There can be a separate fan control circuit or power supply involved which can fail, often when a faulty fan draws excessive current.

The drive heatsink should be kept clear of obstruction.

Failure of the fans causes an increase in temperature which usually results in an "over temperature" fault. There can be a separate fan control circuit or power supply involved which can fail, often when a faulty fan draws excessive current.

The drive heatsink should be kept clear of obstruction.

The capacitors hold a reservoir of charge and filter out the ripple from the three phase rectifiers.

Lifetime generally depends on operating temperature and ripple current (ripple being load dependent) for the particular quality of capacitor used. Capacitors can leak fluid or fail destructively causing additional damage.

Lifetime generally depends on operating temperature and ripple current (ripple being load dependent) for the particular quality of capacitor used. Capacitors can leak fluid or fail destructively causing additional damage.

The power modules reconstruct the 3 phase AC waveform according to the required speed and load requirements of the motor.

Semiconductor power modules, normally of the IGBT type, tend to fail destructively during operation. Failure can be influenced by load, motor condition or deterioration of the control circuit.

Semiconductor power modules, normally of the IGBT type, tend to fail destructively during operation. Failure can be influenced by load, motor condition or deterioration of the control circuit.

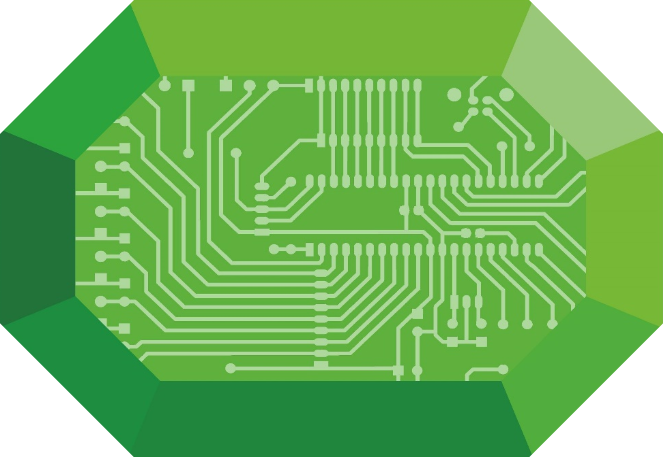

This page gives useful information on how AC drives (VFD's) fail over time and why.

The rectifiers convert the AC input to DC.

Rectifiers are semiconductor devices which can be damaged by surges on the AC supply, for example lightning strikes on the power grid.

Rectifiers are semiconductor devices which can be damaged by surges on the AC supply, for example lightning strikes on the power grid.

The precharge circuit limits the inrush current into the drive at switch on, this extends lifespan and increases reliability.

This circuit can fail over time due to electronic timing issues or stress of load bearing components. The amount of times a drive is powered up can affect this circuit.

This circuit can fail over time due to electronic timing issues or stress of load bearing components. The amount of times a drive is powered up can affect this circuit.

The precharge circuit limits the inrush current into the drive at switch on, this extends lifespan and increases reliability.

This circuit can fail over time due to electronic timing issues or stress of load bearing components. The amount of times a drive is powered up can affect this circuit.

This circuit can fail over time due to electronic timing issues or stress of load bearing components. The amount of times a drive is powered up can affect this circuit.

A circuit is required to switch the power modules to construct the AC waveform to drive the motor.

The circuit uses PWM usually between 2 and 12 KHz. This fast switching stresses capacitors and other components. A significant quantity of power module failures are due to problems in this circuit.

The circuit uses PWM usually between 2 and 12 KHz. This fast switching stresses capacitors and other components. A significant quantity of power module failures are due to problems in this circuit.

The power supply generates all the voltages required to run all the other processes in the drive.

The power supply is vulnerable to age related component deterioration due to a trade off between size and heat dissipation.

The power supply is vulnerable to age related component deterioration due to a trade off between size and heat dissipation.

The rectifiers convert the AC input to DC.

Rectifiers are semiconductor devices which can be damaged by surges on the AC supply, for example lightning strikes on the power grid.

Rectifiers are semiconductor devices which can be damaged by surges on the AC supply, for example lightning strikes on the power grid.

Most drives have fans to keep the heatsink cool. These can be on permanently or may be controlled when the drive is under load, depending on the manufacturer.

Fan failure causes an increase in temperature which results in an "over temperature" fault. There can be a separate fan control circuit or power supply involved which can fail, often when a faulty fan draws excessive current. The drive heatsink should be kept clear of obstruction.

Fan failure causes an increase in temperature which results in an "over temperature" fault. There can be a separate fan control circuit or power supply involved which can fail, often when a faulty fan draws excessive current. The drive heatsink should be kept clear of obstruction.

The capacitors hold a reservoir of charge and filter out the ripple from the three phase rectifiers.

Lifetime generally depends on operating temperature and ripple current (ripple being load dependent) for the particular quality of capacitor used. Capacitors can leak fluid or fail destructively causing additional damage.

Lifetime generally depends on operating temperature and ripple current (ripple being load dependent) for the particular quality of capacitor used. Capacitors can leak fluid or fail destructively causing additional damage.

The power modules reconstruct the 3 phase AC waveform according to the required speed and load requirements of the motor.

Semiconductor power modules, normally of the IGBT type, tend to fail destructively during operation. Failure can be influenced by load, motor condition or deterioration of the control circuit.

Semiconductor power modules, normally of the IGBT type, tend to fail destructively during operation. Failure can be influenced by load, motor condition or deterioration of the control circuit.

We hope this page has been informative. Why not click on our services page from the main menu and see how we could help if your drive fails or why not consider a planned refurbishment if your drive is getting old and exhibiting any issues.

We hope this page has been informative. Why not click on our services page from the main menu and see how we could help if your drive fails or why not consider a planned refurbishment if your drive is getting old and exhibiting any issues.

GENERIC DRIVE

The rectifiers convert the AC input to DC.

Rectifiers are semiconductor devices which can be damaged by surges on the AC supply, for example lightning strikes on the power grid.

Rectifiers are semiconductor devices which can be damaged by surges on the AC supply, for example lightning strikes on the power grid.

Most drives have fans to keep the heatsink cool. These can be on permanently or may be controlled when the drive is under load, depending on the manufacturer.

Failure of the fans causes an increase in temperature which usually results in an "over temperature" fault. There can be a separate fan control circuit or power supply involved which can fail, often when a faulty fan draws excessive current.

The drive heatsink should be kept clear of obstruction.

Failure of the fans causes an increase in temperature which usually results in an "over temperature" fault. There can be a separate fan control circuit or power supply involved which can fail, often when a faulty fan draws excessive current.

The drive heatsink should be kept clear of obstruction.

The capacitors hold a reservoir of charge and filter out the ripple from the three phase rectifiers.

Lifetime generally depends on operating temperature and ripple current (ripple being load dependent) for the particular quality of capacitor used. Capacitors can leak fluid or fail destructively causing additional damage.

Lifetime generally depends on operating temperature and ripple current (ripple being load dependent) for the particular quality of capacitor used. Capacitors can leak fluid or fail destructively causing additional damage.

The power modules reconstruct the 3 phase AC waveform according to the required speed and load requirements of the motor.

Semiconductor power modules, normally of the IGBT type, tend to fail destructively during operation. Failure can be influenced by load, motor condition or deterioration of the control circuit.

Semiconductor power modules, normally of the IGBT type, tend to fail destructively during operation. Failure can be influenced by load, motor condition or deterioration of the control circuit.

A circuit is required to switch the power modules to construct the AC waveform to drive the motor.

The circuit uses PWM usually between 2 and 12 KHz. This fast switching stresses capacitors and other components. A significant quantity of power module failures are due to problems in this circuit.

The circuit uses PWM usually between 2 and 12 KHz. This fast switching stresses capacitors and other components. A significant quantity of power module failures are due to problems in this circuit.

We hope this page has been informative. Why not click on our services page from the main menu and see how we could help if your drive fails or why not consider a planned refurbishment if your drive is getting old and exhibiting any issues.

The precharge circuit limits the inrush current into the drive at switch on, this extends lifespan and increases reliability.

This circuit can fail over time due to electronic timing issues or stress of load bearing components. The amount of times a drive is powered up can affect this circuit.

This circuit can fail over time due to electronic timing issues or stress of load bearing components. The amount of times a drive is powered up can affect this circuit.

The power supply generates all the voltages required to run all the other processes in the drive.

The power supply is vulnerable to age related component deterioration due to a trade off between size and heat dissipation.

The power supply is vulnerable to age related component deterioration due to a trade off between size and heat dissipation.

GENERIC DRIVE

GENERIC DRIVE